Vibration Testing

Vibration Equipment

As specialists in dynamic testing, we provide equipment capable of exerting a 6,000 to 40,000 pound force with the capacity to perform closed-loop control from a single input to multiple channel inputs (from 2 to 32) with averaging or notched channel control. Vibration control systems can be programmed for real time monitoring, scheduled for length of time, or level scaled by dB or percentage, or scaled at various durations at different acceleration levels.

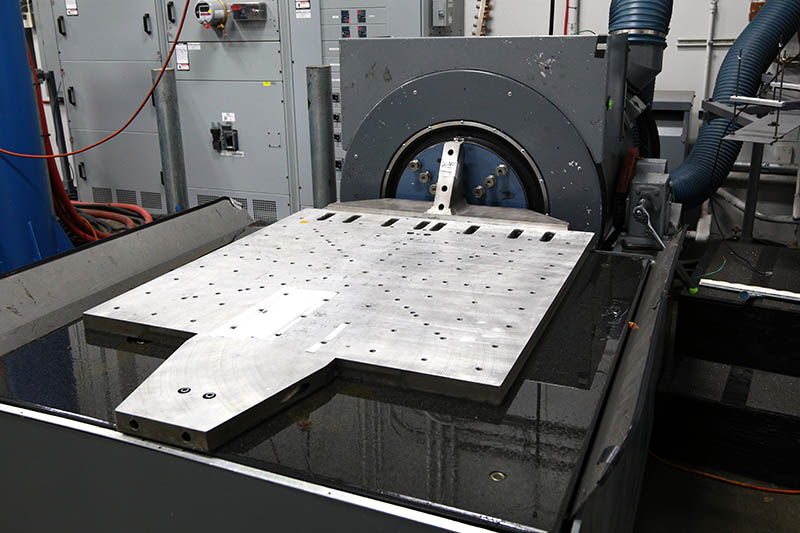

We have electro-dynamic shakers at 2-inch stroke and servo-dynamic shakers at 4-inch stroke with a range of capabilities. Most of our electro-dynamic shakers are attached with slip-plates to perform multi-axis testing. Environment Associates has both Unholtz-Dickie and Ling equipment with large size slip tables to fit most test articles and fixtures.

Vibration Tests

Environment Associates performs vibration tests to MIL-STD-810, RTCA DO-160, MIL-STD-750, MIL-STD-202, as well as ISTA, EN, IEC, and ASTM specifications. We also provide unique tests like gunfire, transportation packaging and NAVMAT screening.

Vibration Test Profiles

Environment Associates can setup and provide the following vibration test profiles:

Sine – Can operate swept sine or fixed frequency sine wave vibration tests that can be controlled for acceleration, velocity or displacement

Sine on Sine –Operating a mixed-mode tests with multitude sine tones.

Random –Controlled spectrum random tests with spectrally shaped gaussian amplitudes

Sine on Random – Operating a mixed mode test with sine tones on a random background

Random on Random –Operating controlled spectrum random tests with swept random tones

Shock – Standard classical shock pulses

SRS – Shock Response Spectrum analysis.

Field Data Replication – Reproduce actual acceleration waveforms measured in the field.

Vibration and Mixed Environments

When called upon, we provide specialized environments that include temperature, humidity, rapid temperature change, salt spray and combination environments with our vibration tests that can be supervised 24/7 with on-site monitoring or remote monitoring.

Vibration Fixtures

The key to developing a great test plan is having vibration fixtures that are non-resonance, controllable configurations, manufactured from aluminum or magnesium materials that hold single or multiple parts for test. Many times, we stock pre-configured expansion heads and plates that can be easily incorporated to your test article, which will lower your fixture cost and accelerate your time to test. Each fixture is tested for performance and tuned to perform at its best. Environment Associates can design and manufacture a fixture for your testing needs. If you would like to know more about our vibration test fixture group then click here.

Vibration Monitoring

Real-time performance assessment (Vehicle or Machine Vibration Data) can be provided by our systems technicians by instrumenting your product with accelerometers, thermal couples, stress and strain guages or other measurement devices for laboratory or in-field monitoring. These services can provide your design group with needed information about product use and conditions. We can provide this data to your FEA design staff to determine stress levels and energy.

Additional Resources

PLEASE NOTE, that while 3/8” hardware is our standard mounting preference at Environment Associates, we are also capable of adapting our dynamics test equipment to accept 1/2” hole pattern fixtures. Please contact our sales team if you require 1/2” hole pattern mounting so we can properly accommodate your testing needs.